Manufacturing Process Image of MLCC

2:41

Most of Murata’s core technologies have been cultivated through producing Multilayer Ceramic Capacitors. This video shows the manufacturing process and related technologies.

Related Videos

In Capacitor

-

Play video Replacement evaluation of electrolytic capacitors

Replacement evaluation of electrolytic capacitors

Extensive improvements in the characteristics and low profiles can be achieved, by replacing electrolytic capacitors with conductive polymer capacitors or monolithic ceramic capacitors.

7:34

-

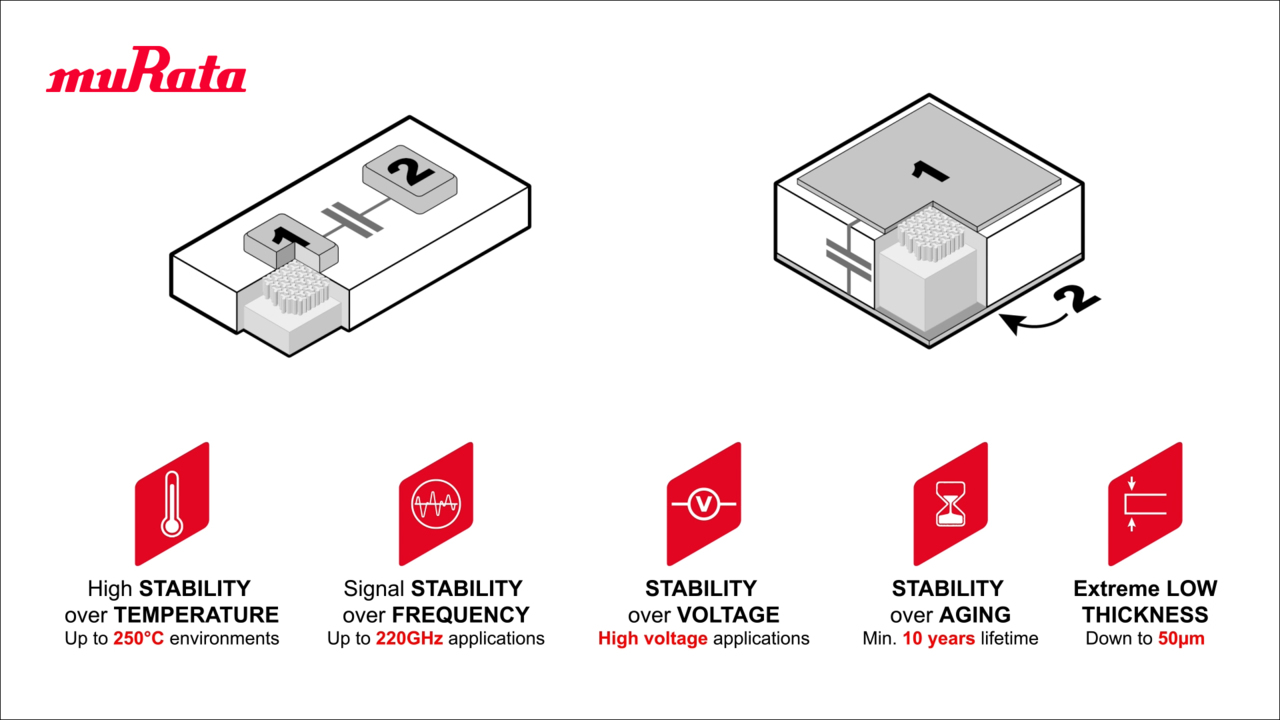

Play video Silicon Capacitor Generalities

Silicon Capacitor Generalities

This video explains the general information and features of Silicon Capacitor.

1:07

-

Play video Solving problems with the ECAS series: High capacitance and thin package

Solving problems with the ECAS series: High capacitance and thin package

A single Murata ECAS series polymer aluminum electrolytic capacitors with maximum capacitance of 470 μF and minimum thickness of 2.0 mm can take the place of multiple conventional capacitors.

1:59

-

Play video “ECAS Series” Polymer Aluminum Electrolytic Capacitors

“ECAS Series” Polymer Aluminum Electrolytic Capacitors

Let’s take a look at the high capacitance capacitor ECAS series with a maximum 470 μF that exceeds MLCC.

2:19

-

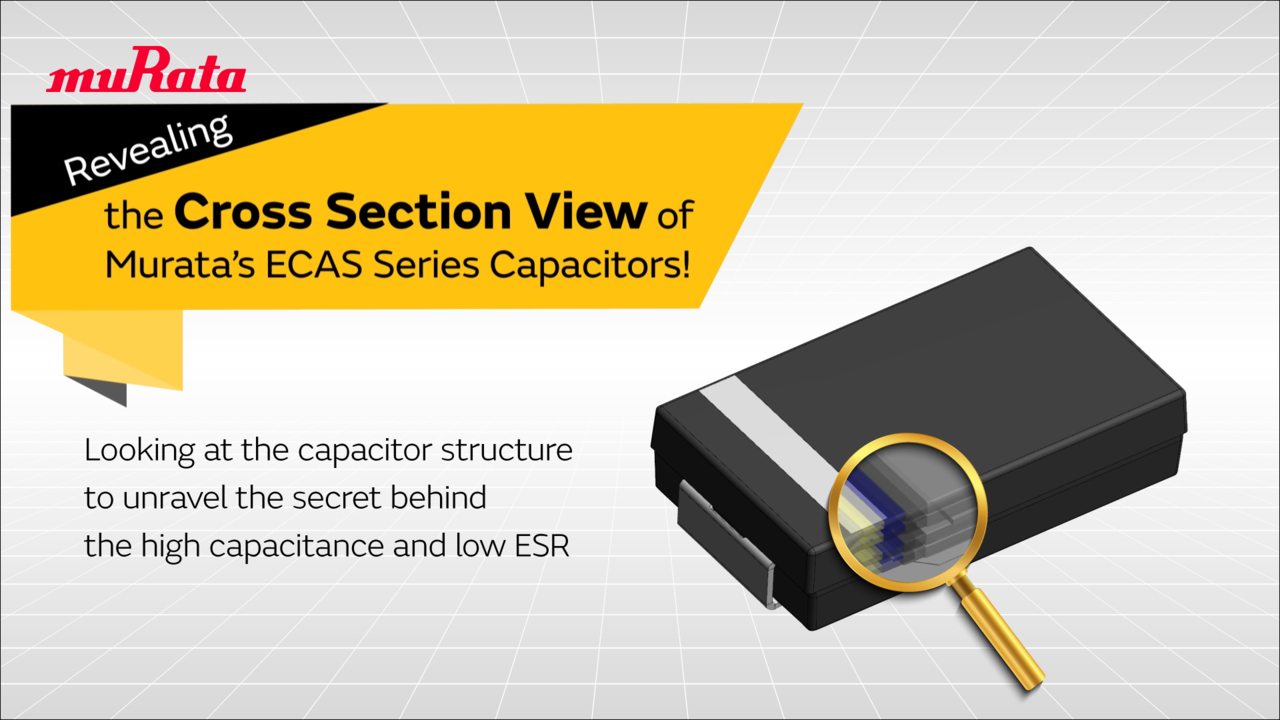

Play video Revealing the Cross Section View of Murata’s ECAS Series Capacitors! Looking at the capacitor structure to unravel the secret behind the high capacitance and low ESR

Revealing the Cross Section View of Murata’s ECAS Series Capacitors! Looking at the capacitor structure to unravel the secret behind the high capacitance and low ESR

What is the structure of the high capacitance and low ESR ECAS series polymer aluminum electrolytic capacitors? Let’s examine the strengths and design innovations of ECAS series capacitors by looking at their internal structure.

3:01

-

Play video Miniaturization

Miniaturization

This video explains why does size matter. It shows Silicon Capacitor offer further performances thanks to their low x, y and z dimensions.

2:18